EITEC-PROTEC Aluminium System

The Core Piece

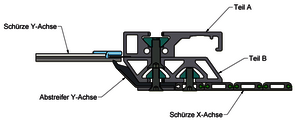

The the entire modular systems core piece is the multi-functional two-part guide, which can be pieced together from two separate aluminium press-drawn sections.

The two profile components are joined – depending on application – by screws via the integrated profile slots. Other parts can be externally installed using the slot nuts. The assembly system thus allows countless new attachment versions, simply and flexibly.

Guides – X Axis at Top

The combination of two profile A components allows the realisation of all standard guides for the load-bearing guide at the top: for aprons with steel bolts, for aprons with new short steel bolts, and for heavy roller aprons.

As slide profile for aprons with steel bolts a plastic profile, also newly developed, has been introduced which remains perfectly in the aluminium profile by simply clamping or inserting – without drilling and without screw connections!

Guides – X Axis at Bottom

For steel band guidance from the bottom, join guide profile A and guide profile B. Part A has a recess to take up the steel band. Joining the two parts with screws automatically lamps the steel band.

Profile part B is mounted with the slotted side inwards: the inclination of wiper the profile contour ensures that chips are led downwards over the visible side and not into the guide.

No additional wiper is required.

Assembly

Assembly of integrated apron cover systems without welding and without drilling. Simply join the pre-cut profile halves with screws. Simply insert the slide profiles and running slats.

The system is self-supporting, with no additional supporting frame. Worms and deflections are easily integrated via standard attachment kits.

The wiper profile specially developed for the system fits perfectly to the profile contour. The profile slots allow flexible assembly interfaces for installation in the machine.

Maintenance

For replacement of wear parts the system remains completely installed in the machine. The wiper frames are directly accessible, so that the wipers can be replaced without dismantling. With the rail open you can easily remove and replace slide profiles by tipping.

The split design of the front guide profile simplifies replacing the apron: opening the guide in the end positions of the X axis allows the removal of an apron.

The profile also has an integrated functionality to clamp back and fix the steel band, which also simplifies replacing the apron.

Overview of Special Advantages

- Profile universally usable in system, giving high flexibility for assembling and dismantling

- Simple calculation, design and assembly thanks to standard components

- Standard connectors ("connector kit") universally usable in system

- Countless new fixing positions possible

- No welding!

- No painting required

- No additional supporting frame required

![[Translate to English:] [Translate to English:]](/fileadmin//user_upload/Images/Produktbilder/Stahllemellen/stahllamellen-hinten.jpg)